coating thickness measurement methods pdf|coating thickness measurement methods : wholesaler coatings on steel. The eddy current method allows you to measure insulating coatings (paint, lacquer, plastic, anodizing) on non-ferrous metals. The coating thickness gauge has a graphical LCD touch panel with an innovative operator guidance and a resolution of 320x480 pixels. The menu guidance is in German and English,

C3 e C4 são as proteínas do complemento medidas com frequência. A atividade do complemento total (CH50 ou CH100) pode ser determinada se o médico suspeita de .

{plog:ftitle_list}

7 de fev. de 2024 · Athletic x Atlético-MG - 4° rodada do Campeonato Mineiro 2024. Data-Hora: 08 de fevereiro, 21h; Local: Arena Sicredi, São João del-Rei; Árbitro:Vinicius Gomes do Amaral;

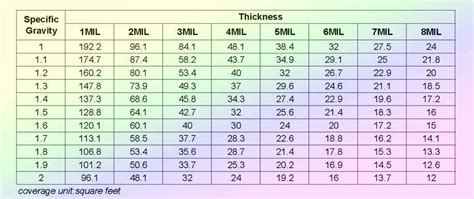

powder coating thickness chart

Laboratory Pulp Disintegrator vendor

In this review, we analyse some of the most appropriate methods for determining the thickness of metallic coatings. In doing so, we classify the techniques into two categories: (i).1. Scope. 1.1 This test method covers the use of X-ray spectrometry to determine thickness of metallic and some nonmetallic coatings. Methods most frequently used for thickness determination of technically important coatings are mechanical methods, like stylus profilometry or ball crater (BC) measurements, 8,12,13 or microscopic .METHOD OF TEST FOR MEASURING EPOXY COATING THICKNESS ON STEEL REINFORCING BARS, WELDED WIRE MESH AND DOWEL BARS USING TYPE 2 GAGES A. SCOPE This test method describes the procedure for nondestructive spot thickness measurements of non-magnetic green flexible (ASTM A775) and purple/gray rigid (ASTM .

State-of-the-Art Coating Thickness Measurement 2 Coating Thickness Measurement Instruments FMP10, FMP20, FMP30 and FMP40 The Fischer proven portable instruments with exchange- able probes allows for non-destructive and highly pre-cise measurements of coatings. Whether for quality control in a manufacturing process or incoming inspec-

coatings on steel. The eddy current method allows you to measure insulating coatings (paint, lacquer, plastic, anodizing) on non-ferrous metals. The coating thickness gauge has a graphical LCD touch panel with an innovative operator guidance and a resolution of 320x480 pixels. The menu guidance is in German and English, Thickness dramatically affects the functionality of coatings. Accordingly, the techniques in use to determine the thickness are of utmost importance for coatings research and technology. In this review, we analyse some of the most appropriate methods for determining the thickness of metallic coatings. In doing so, we classify the techniques into two .Dry film thickness (DFT) can be measured using two methods: destructive thickness measurement, where the coating is cut to the substrate using a cutter; and non-destructive coating thickness measurement, using techniques which do not damage the coating or the substrate such as magnetic, magnetic induction and eddy current thickness measurement .AND METHODS OF MEASURING SURFACE HARDNESS AND THICKNESS OF COATINGS Technical Report TR-#105(Rev.Ø) 19650 Pauling Foothill Ranch, CA 92610-2610 Tel (949) 460-2100 Fax (949) 460-2300 Email: [email protected] www.balseal.com Spinozastraat 1 1018 HD Amsterdam The Netherlands Tel +31 20 638 6523 Fax +31 20 625 6018 Email: [email protected]

Coating thickness measurement/Dry film thickness measurement is used to determine the thickness of coatings on components and to monitor the coating process. Our measuring instruments solve a wide range of applications in coating thickness measurement. Whether single or multilayer coatings, painted or galvanized, magnetizable or conductive.

a Nonferrous Metal Base3 E 1316 Terminology for Nondestructive Examinations4 G 12 Test Method for Nondestructive Measurement of Film Thickness of Pipeline Coatings on Steel5 2.2 International Standard: ISO 2178 Nonmagnetic Coatings on Magnetic Substrate— Measurement of Coating Thickness—Magnetic Method6 1. Appendix 6: Method for Measuring the Dry Film Thickness of Coatings on Edges. For decades, the industry was cautioned about taking coating thickness measurements within 1 inch of an edge, let alone on an edge. . Prior to measurement of coating thickness on edges, the gage and probe should be verified for accuracy by placing a thin, flexible .the method. For thin coatings, this measuring uncertainty ( in absolute terms ) is constant, independent of the coating thickness, and, for a single measurement, is at least O-5 pm. For coatings thicker than about 25 pm this un- certainty is an approximately constant fraction of the coating thickness. 4.1.2 If measuring coatings of thickness 5 tLm

how to measure paint thickness

5.1 Thickness of Coating ÑThe precision of a measurement changes with coating thickness depending on method used and instrument design. Generally, the precision is a percentage of the coating thickness except at the lower end of the ranges where it is a Þxed thickness. 5.2 Magnetic Properties of Basis Metal ÑMagnetic thick-Designation: D 1005 – 95 (Reapproved 2001) Standard Test Method for Measurement of Dry-Film Thickness of Organic Coatings Using Micrometers1 This standard is issued under the fixed designation D 1005; the number immediately following the designation indicates the year of original adoption or, in the case of revision, the year of last revision.In ISO 2178:2016 the term "coating" is used for material such as, for example, paints and varnishes, electroplated coatings, enamel coatings, plastic coatings, powder coatings, claddings. NOTE This method can also be applied to the measurement of magnetizable coatings on non-magnetizable base metals or other materials (see ISO 2361).4.2 For some coating-substrate combinations, the beta back-scatter method is a reliable method for measuring the coating nondestructively. 4.3 The test method is suitable for thickness specification acceptance if the mass per unit area is specified. It is not suitable for specification acceptance if the coating thickness is

1.1 This International Standard specifies methods for measuring the thickness of metallic coatings by the use of X-ray spectrometric methods. 1.2 The measuring methods to which this International Standard applies are fundamentally those that determine the mass per unit area.

4.2.5 Measure the dry coating at the number of spots specified in Section 5. 4.2.6 Subtract the base metal reading from the gage read- ing to obtain the thickness of the coating. 4.3 CALIBRATION, VERIFICATION AND MEASUREMENT: TYPE 2"CONSTANT PRESSURE PROBE GAGES 4.3.1 Different manufacturers of Type 2 (constant pressure The determination of thickness has a fundamental importance in all fields in which the implementation of films and coatings are required and takes a crucial role in the electroplating sector.

8.1 Inherent in the test method is a measuring uncertainty that, for thin coatings, is constant and independent of the coating thickness, and, for a single measurement, not less than 0.5 µm (0.02 mil); for thicknesses greater than about 25 µm (1 mil), this uncertainty is proportional to the coating thickness.DOI: 10.1016/J.INFRARED.2016.04.028 Corpus ID: 111430980; A new measurement method of coatings thickness based on lock-in thermography @article{Zhang2016ANM, title={A new measurement method of coatings thickness based on lock-in thermography}, author={Jin-yu Zhang and Xiang-bin Meng and Yong-chao Ma}, journal={Infrared Physics \& Technology}, .2. ASTM B568-98 (2009) Standard Test Method for Measurement of Coating Thickness by X-Ray Spectrometry. 3. ISO 3497-2000-Measurements of coating thickness – X-ray spectrometric methods. Conclusion To ensure customer coating specifications are met, quality control at-line, online or during final product inspection is a necessity.V arious methods of NDT are used for the measurement of coating thickness – paint thickness, plating thickness, anodising etc. These methods may be X-ray, electron backscatter, magnetic, etc and the Table gives a broad guide to the most appropriate methods for various coatings and substrates.

Metallic coatings — Measurement of coating thickness — Profilometric method 1 Scope This document specifies a method for the measurement of metal coating thickness by first forming a step between the surface of the coating and the surface of its substrate and then measuring the step height using a profile recording instrument.Metallic coatings — Measurement of coating thickness — Profilometric method. This document specifies a method for the measurement of metal coating thickness by first forming a step between the surface of the coating and the surface of its substrate and then measuring the step height using a profile recording instrument.

Coatings or films are applied to a substrate for several applications, such as waterproofing, corrosion resistance, adhesion performance, cosmetic effects, and optical coatings. When applying a coating to a substrate, it is vital to monitor the coating thickness during the coating process to achieve a product to the desired specification via real time .atomic number of the coating layer, and the energy of the emitted lines used. In the past, XRF has been used to measure coat-ing thickness using stationary or benchtop instru-ments. However, the specimen must be brought inside or close to the analyzer chamber for analysis using stationary XRF methods, making measuring coating thickness on large .Metallic and oxide coatings — Measurement of coating thickness — Microscopical method. Skip to main content. Applications . ISO 1463:2021 Metallic and oxide coatings — Measurement of coating thickness — Microscopical method. Published (Edition 4, 2021) ISO 1463:2021. ISO 1463:2021. 78374. Language. Format. CHF 96. Add to cart .

WEB28 de jan. de 2024 · About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright .

coating thickness measurement methods pdf|coating thickness measurement methods